Portable or bench hardness testers? The challenge

In a survey among LinkedIn users, we asked different professionals whether they used hardness testers in their line of work.

We received 126 answers as described here below:

44% YES

23% NO

33% used them in the past.

Of course, hardness testers are not all the same. And each one is suitable for a specific application. We invite you to keep reading to learn more about these non-destructive testing instruments.Click here to check the Linkedin poll.

Photo by www.canva.com

What are hardness testers?

According to the famous encyclopedia Britannica, a hardness tester is a “device that indicates the hardness of a material, usually by measuring the effect on its surface of a localized penetration by a standardized rounded or pointed indenter of diamond, carbide, or hard steel.”

Simply put, hardness testers are non-destructive testing instruments that allow you to determine, based on the applicable standard, the value of hardness of different materials, including, but not limited to:

- Steels and steel alloys

- Aluminum and aluminum alloys

- Brass

- Copper

- Plastic

- Thermoplastic elastomers

Photo by www.canva.com

How is hardness measured?

The typical hardness test involves an object called indenter which is pressed on and into the surface of the material being tested.

The indenter must have specific dimensions and must be loaded with a specific pressure depending on the type of tester.

Afterwards, the hardness is determined by measuring the depth of the penetration or the area of the indentation. Measuring one or the other will depend on the type of hardness test being performed. The most common ones include:

- Leeb hardness test

- Rockwell hardness test

- Vickers hardness test

- Brinell hardness test

- Shore hardness test

Why is hardness testing so important?

Knowing the hardness of the materials used on a piece or structure is important for various reasons. First of all, hardness testing allows you to assess important properties such as strength, ductility and wear resistance.

Therefore, with the information obtained, it is easy to determine whether the material is suitable for the application at hand or not and whether further surface treatment is necessary to achieve the desired results.

Also, it can be used to verify the quality of the material and determine if maintenance is required.

What are the different types of hardness testers?

As mentioned above, there are different hardness testers for different applications. So, let’s take a look at the most common ones.

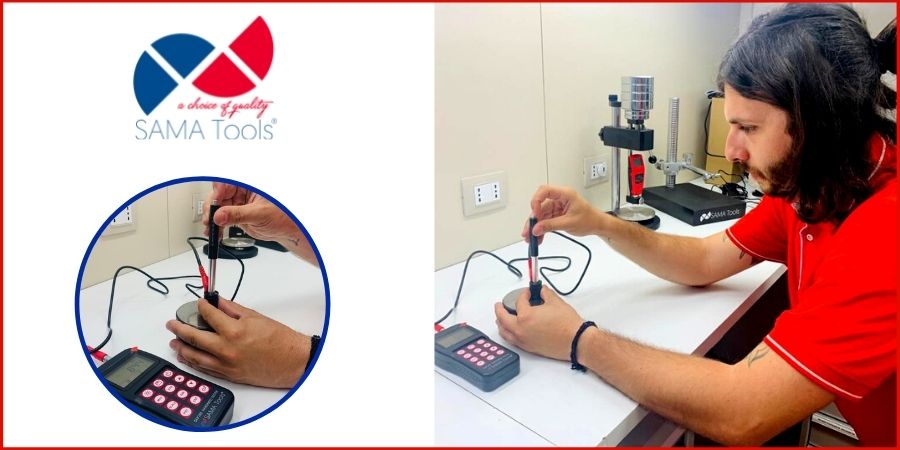

Leeb Hardness Testers

As the name suggests, these testers are based on the Leeb hardness test as defined in the ISO 16859 and ASTM A956 standards. It is a dynamic test method where the ratio of rebound velocity to impact velocity of a moving impact body is used to determine the hardness.

Leeb hardness testers are usually employed for testing various metals and alloys, and they are a great choice when checking incoming and outgoing goods, for quality control activities, and maintenance of structures and workpieces subject to wear.

Here at SAMA Tools, we offer 3 different Leeb hardness tester models :

- Leeb hardness tester SAP180, with D type impact probe and a test block.

- Touchscreen Leeb hardness tester SAP550, with touchscreen display and a wireless printer for printing reports on the go, which is great for quality control activities on the field.

- Pen type Leeb hardness tester SAP650, a compact and highly accurate tester with automatic detection of impact direction with a wireless interface.

Barcol Hardness Testers

Similar to the previous type, these instruments are named after the hardness test that they perform, the Barcol test.

This test is usually used on softer materials such as aluminum, aluminum alloys and some plastics. It was previously known as Barber-Colman Impressor since Walter Colman developed this test as a portable method during the World War II.

The process uses the indenter or “impressor” to press on the material and measure how deep the tip of it penetrates.

We offer 2 Barcol hardness tester models :

- Analogue Barcol hardness tester

- Digital Barcol hardness tester

Webster Hardness Testers

This simple model of hardness testers allows to measure the hardness of soft materials such as soft steels, aluminum, brass and copper. Moreover, it can be applied on different geometries and very small thickness values.

The values obtained can be easily converted to the common scales, including Vickers, Rockwell and Brinell.

We offer 3 versions of the Webster hardness tester:

- SAMW-20

- SAMW-20a

- SAMW-20b

The main difference is the range of thickness and diameter they can be applied on.

Shore Hardness Testers

Shore hardness is defined as the resistance of a material to penetration from a spring-loaded needle-like indenter.

By definition, we can easily conclude that the process to perform a hardness test with a Shore hardness tester is very similar to the one with the Barcol tester.

There are different scales for Shore testing, the most common ones being the Shore A scale for soft elastomers like rubber, and Shore D for hard elastomers and other polymers like thermoplastics and thermosets. This makes Shore hardness testers a great option for quality control activities in rubber and plastics industries and for maintenance on ring nuts and gaskets.

We offer 3 different versions of the Shore hardness testers:

- Analogue Shore Hardness Testers

- Digital Shore Hardness Testers

- Pro Digital Shore Hardness Testers

The last one in the list is the most powerful of all, since it can handle more than the two scales mentioned above, and it comes with many other interesting features.

We also offer special stands for more accurate and repeatable results, and Shore test blocks for verification and calibration purposes.

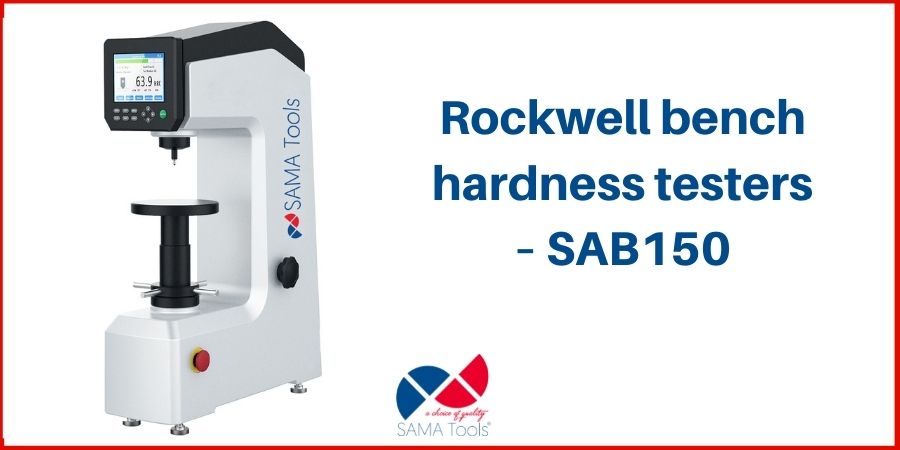

Bench Hardness Testers

The most specialized hardness testers in the market are usually bench hardness testers, since they offer a higher accuracy and repeatability. Therefore, they are the favorite option for metrological laboratories and applications which require the maximum of these two aspects.

These testers work with the indentation principle by applying a constant load over a specific period of time on an indenter which is in contact with the sample. They can use indenters of different sizes, shapes and materials, thus providing the possibility to work with different standards and scales with the same device.

We offer 5 versions of bench hardness testers, some of them are manually operated and others which are motorized. The versions are:

- SAB150-B which is manual, analogue and works with Rockwell A, B and C

- SAB150-BM which is motorized, analogue and works with Rockwell A, B and C

- SAB150-B/DGT which is manual, digital and works with Rockwell A, B and C

- SAB150-BM/DGT which is motorized, digital and works with Rockwell A, B and C

- SAB187,5-B which is motorized, analogue and works with Rockwell A, B and C, Brinell and Vickers hardness scales. It comes with a microscope.

All of our bench hardness testers come with a diamond cone indenter and corresponding test blocks.

So, which hardness tester is used the most?

According to the poll, most of the participants who claim to use it or have used it in the past, say they have used the bench hardness tester. This is followed by users of shore hardness testers and Leeb hardness testers. Last but not least are the Webster and Barcol hardness testers.

The most common answers to what it was used for:

- Inspection on workpieces after hardening to ensure durability.

- Controling of incoming goods.

- Recognizing the hardness of the material to be welded.

Photo by www.canva.com

How can I select the best hardness tester for my needs?

When selecting the best hardness tester for your needs, there are different things to consider. The most important are:

- Type of material tested

- Requirement of standard compliance

- Material’s approximate hardness

- Sample size and geometry

- Mounting requirement

- Number of samples to be tested

- Required accuracy and repeatability

Photo by www.canva.com

If you want to see all the hardness testers that we offer and select the right one for your needs, just click here.

Instead, if you are not sure yet or have any doubts about hardness testers, we recommend you contact us and one of our specialists will gladly assist you.

Video summary: Portable or bench hardness testers? The challenge