Although many people may think that achieving, the right color of a product is simple, in reality there is a sequence of very important of steps to follow in order to achieve the required color. We’ve already mentioned this in our recent article dedicated to our Romanian client, Benjamin Paints. Today we will see how to examine and check the color of molds and plastic components.

For an injection mold manufacturer, for example, finding defects in the color of an object represents a failure in quality control. This results in the product being sold at a discounted price or even discarded, even before it is placed on the market.

That is why it is so important for the manufacturer to get the correct color.

Failure to achieve the correct color of a product before placing it on the market implies a wide range of issues that involve not only the economic aspect, but also puts the reputation and reliability of the brand at risk. Not to mention functionality issues: for example when highly reflective colors that are required for certain applications, get unsatisfactory results.

Getting the colors right is essential, but how?

Photo by Canva PRO

How can manufacturers check the color of molds and plastic components?

You may have already heard that colors are identified subjectively and emotionally. There is a lot of truth to this and precision work is at the base of it, by making sure that the color obtained is exactly the one specified.

Fortunately, technology has taken color measurement and control to the next level. While visual assessment is still the first step, there are tools like professional colour difference meters and color matching cabinets, that make color quality control much easier and more accurate.

But having state-of-the-art instruments isn’t the only step manufacturers need to take to get the right colors. Getting the best results involves a gradual process where every single detail has to be considered.

Here are some of the most important aspects that a manufacturer needs to achieve the best results:

Having a trained eye: visual inspection

As mentioned above, the first filter for color control is through visual inspection. When color differences are noticeable, having an expert eye that carries out this first inspection will save time and resources. However, when the differences become difficult for the eye to see, it is then necessary to use specific measuring instruments.

Using the right tools: colour difference meters and color matching cabinets

To check the color quality, the go-to instrument is the colour difference meter (see the article “Colour difference meter: what it is and why it is important”).

In some cases, a colorimeter is all you need. However, there are some cases where tolerances require the highest level of accuracy possible or the nature of the product and the material used to manufacture it, require other types of instrumentation to be used. For example, a color matching cabinet can come in handy when a neutral environment with uniform light is required.

How to use a colour difference meter and a color matching cabinet?

Having the best measuring instruments on the market is not enough, if you do not know how to use them correctly.

Having an expert eye for visual inspection coupled with training for correct instrument operation and correct interpretation of the results, makes a big difference in ensuring that the quality control process is 100% reliable.

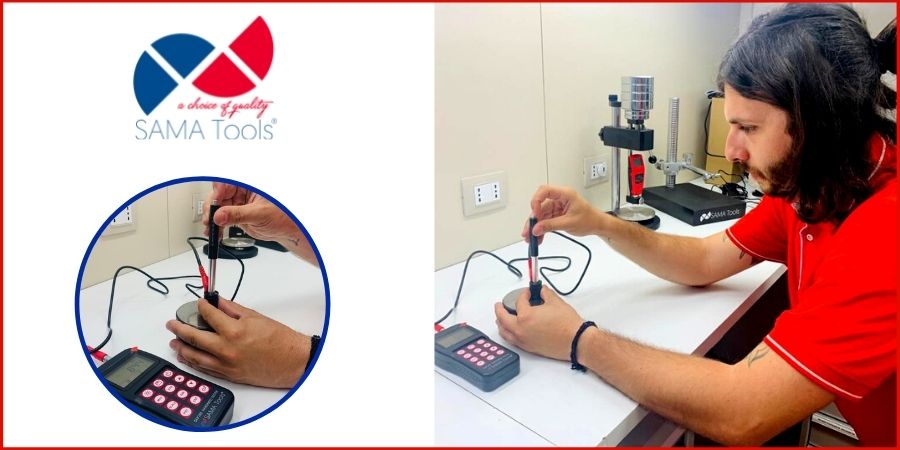

Those who buy SAMA Tools name-brand measuring instruments will be guided step by step, via remote or in person, when they choose to combine our training courses with the purchase of an instrument.

On-site training courses for colour difference meters and color matching cabinets

Nowadays, many companies require training courses combined with the installation of the instruments/equipment, directly on-site, in order to fully understand how to use the tools effectively and straight away.

Our trained technicians explain how to use the colour difference meters in order to be able to compare the various components produced, with all the reference standards imposed by their customers, and thus identifying any delta deviations from the color values. This evaluation allows them to make all the necessary changes in order to ensure excellent quality while avoiding any kind of dispute.

However, many sectors work a lot with translucent objects, which is why it is imperative to have a color matching cabinet as well.

The cabinet allows you to recreate a neutral environment with uniform light, where the tested components are not affected by anything around them.

Thanks to our courses, the instrument features are explained in every detail, allowing for a better assessment of the differences between the various colors, mainly in transparent molds, which are hardly visible to the naked eye.

Our customers can thus ascertain whether the production is in line with the required standards, or not.

SAMA Tools colour difference meter and Color matching cabinet training course

After the training course, instrument adjustment and periodic calibration.

As human beings, we are not perfect. Even when well prepared, human error is present, so establishing clear procedures for how to take measurements is essential to minimize human error.

Furthermore, each certified company can guarantee higher quality thanks to specific procedures.

Not only people, but measuring instruments can also sometimes be wrong, which means that periodic calibration and adjustments should be included in these procedures.

Quality control in molding

Many S.A.M.A. Italia clients work in the field of molds and plastic components. These are often activities within the automotive and household appliances sectors.

To fulfil their mission, they work hard to find accurate and reliable tools that can improve and optimize the work surrounding quality control.

Our customers carry out quality control inspections in order to understand how much the colors of their productions differ from the reference standards dictated by the orders they receive.

SAMA Tools and color control of plastic molds

Companies that rely on us as their main supplier of instruments for their quality control activities, always receive professional advice from our qualified technicians who analyse their production to better understand what their specific needs are.

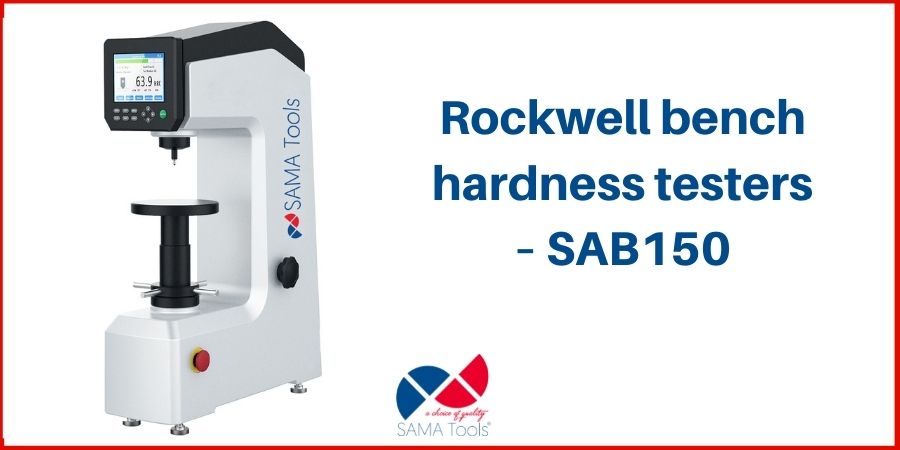

After this preliminary consultation, which is included in our service, customers who are interested in color measurement and control generally, purchase the SA230 colorimeter and / or the SACAS276 color matching cabinet.

SAMA Tools Consulting and technical explanation

How to reach us

In addition to color quality control instruments, we offer a wide range of non-destructive testing tools for a variety of applications.

Buying a SAMA Tools name-brand instrument gives you the security of being able to choose, at any time, the right training for your Quality Control, without wasting time.

Customer satisfaction is our main goal and we would be more than happy to see you become one.

So, if you need help choosing your color quality control instruments, you can always count on our technical advice.

Contact our technical department and call us at 0584/392342 – 0584/392453 or, alternatively, fill out the online form to contact us in writing.