Quality control in the precision machining industry

In the precision machining industry, there arevarious aspects to consider in order to achieve the best possible results, otherwise, the word “precision” would be irrelevant. Today we will be talking about the role played by the bench hardness tester in this sector.

In fact, the hardness of the material is very important, in addition to the dimensional requirements of a piece, which usually has narrow dimensional tolerances.

In addition, it’s important to check all the necessary aspects to achieve high precision and to comply with the requirements of the part being manufactured while keeping repeatability. This is essential for all players involved in the precision machining industry.

Photo by www.canva.com

How to control material hardness in precision machining?

The answer to this question is by means of a hardness tester. As we discovered in a recent survey, hardness testers are commonplace among different industrial sectors. Of course, why and how they use this tool to control material hardness varies from one sector to the other, which is why there are different types of tests.

Hardness testing allows you to assess important properties such as strength, ductility and wear resistance, which is why it is very important for precision machining. That is why it is best to use bench hardness testers.

In photo: user with Multifunctions shore digital hardness testers – SA6610

Bench hardness testers are the most specialized instruments in the market, providing high accuracy and repeatability, which are the main requirements of precision machining.

The test is performed by indenting the part being tested by applying a constant load over a specific period of time on an indenter. The shape, the size, the material and the mass of the indenter determine the hardness scale read by the instrument.

Bench hardness testers provide the precision machining industry the following benefits:

- Possibility of using indenters of different sizes, shapes and materials.

- Possibility to work with different standards and scales.

How is complying with tight dimensional tolerances possible in precision machining?

Apart from working with the best machining tools, and having trained machinists, precision machining companies need to be able to verify the dimensions of the parts after the machining process is finished.

While calipers and other measuring instruments can be used, high expertise from the operator is required to achieve accurate and repeatable measurements. Moreover, some geometries may be complex with angles and other shapes that make the measuring process more challenging.

Therefore, a useful tool to verify the final dimensions and tight dimensional tolerances is the gauge block.

Photo by www.canva.com

A gauge block consists of a worked parallelepiped with two opposing parallel faces, spaced apart by a precise altitude (nominal thickness). These blocks provide the following benefits for the precision machining industry:

- Possibility to use them in series with arithmetic progressions which can be combined to create other gauges.

- Possibility to use them as a template.

- Possibility to perform go/no go controls for dimensional compliance.

- No need to use other measuring instrument.

- Good resolution for dimensional tests.

Hardness and dimensional compliance at Nuova Artegiani e Tranquilli Srl

Nuova Artegiani e Tranquilli Srl is a company dedicated to providing precision machining services while ensuring high quality and repeatability.

The company was founded in 2019, but it counts on the 20 years of experience by its founders, Paolo Artegiani and Massimo Tranquilli.

www.nuovaartegianietranquilli.business.site

Since the beginning, they have strived towards excellence by working with the best providers in their sector, boasting a 600 square meter infrastructure that includes a workshop with top-notch technology for precision machining.

They have taken steps to guarantee hardness and dimensional compliance from the most demanding clients.

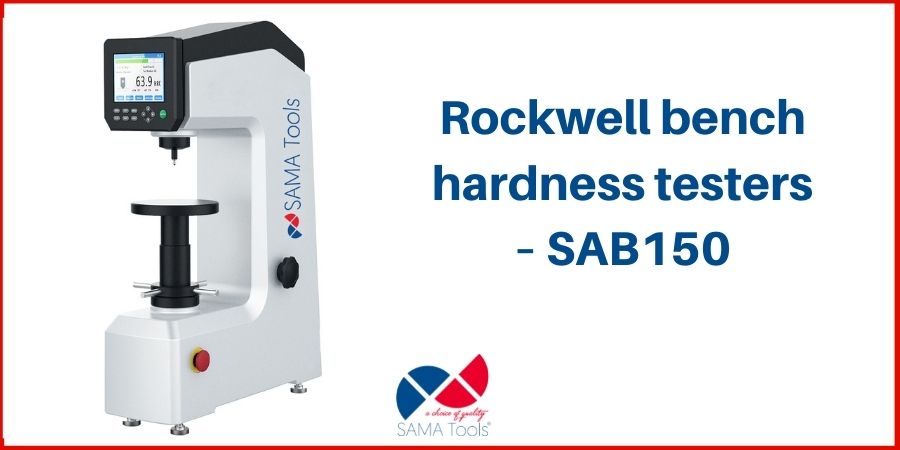

For hardness tests they have recently chosen the SAMA Tools Rockwell bench hardness tester – SAB150, a bench hardness tester that ticks all the boxes for the requirements of precision machining, as it offers maximum accuracy and repetability.

In photo: Rockwell bench hardness testers – SAB150

Moreover, they have also chosen our gauge block set consisting of a series of gauge blocks to help verify compliance to the tightest tolerances in the market.

With these two instruments, Nuova Artegiani e Tranquilli Srl can be sure they will be complying with the highest standards while take advantage of:

- Simplicity – they do not require the operator to have a lot of experience. Almost anyone can work with these instruments.

- High accuracy – a must in precision machining.

- Verifiability – proper calibration provided.

Regarding this final characteristic, we provide calibration services which includes laboratory test reports and/or ACCREDIA calibration certificates for both our own SAMA Tool name-brand instruments and equipment already possessed by our customers.

You can learn more about this service by clicking here.

Do you have a precision mechanical workshop?

This video might interest you!

Final thoughts

Besides, hardness testers and gauge blocks, we offer a wide variety of non-destructive testing tools for different purposes.

Because our mission is to assist our customers in their quality control activities, we strive to provide them with the best solutions to cover their needs.

Go to our catalogue section to see the wide range of instruments that are available.

Nuova Artegiani e Tranquilli Srl is an example of how customer’s satisfaction is our main goal, and we would be more than happy to see you becoming one our satisfied customers.

So, if you need help with hardness control and dimension compliance, or would like advice on the best instrument for your specific case, do not hesitate to contact our technical department.

Photo by www.canva.com

You can call us at 0584/392342 – 0584/392453 .

Would you rather write to us? Our email is sales@samatools.it