The glossmeter is a tool used to measure the shine and gloss of surfaces. Before reading about why to choose the three-angle glossmeter for painted and polished surfaces, let’s see where it’s mainly used.

Where is the glossmeter used?

The glossmeter is employed in many sectors that work with painted and polished surfaces. The main industries that use this device are:

- Automotive

- Furniture manufacturing

- Metal polishing

- Industrial painting

In general, the glossmeter is used in any area where the surfaces must be high quality and meet specific standards of shine and gloss.

How does the glossmeter work?

The glossmeter releases a beam of light on the object’s outer surface and measures the intensity of the reflected light. Based on this principle, the glossmeter can determine the degree of gloss of the surface. We’ve already written an article on the physical principles of the glossmeter, which you can read about.

There are several types of glossmeters, each of which is designed to obtain precise measurements based on the detection geometry and the degree of gloss of the surface. For example, some are equipped with three measuring angles, which allow accurate measurements regardless of the degree of gloss of the surface.

The SAMA Tools three-angle glossmeter is ideal for painted and polished surfaces

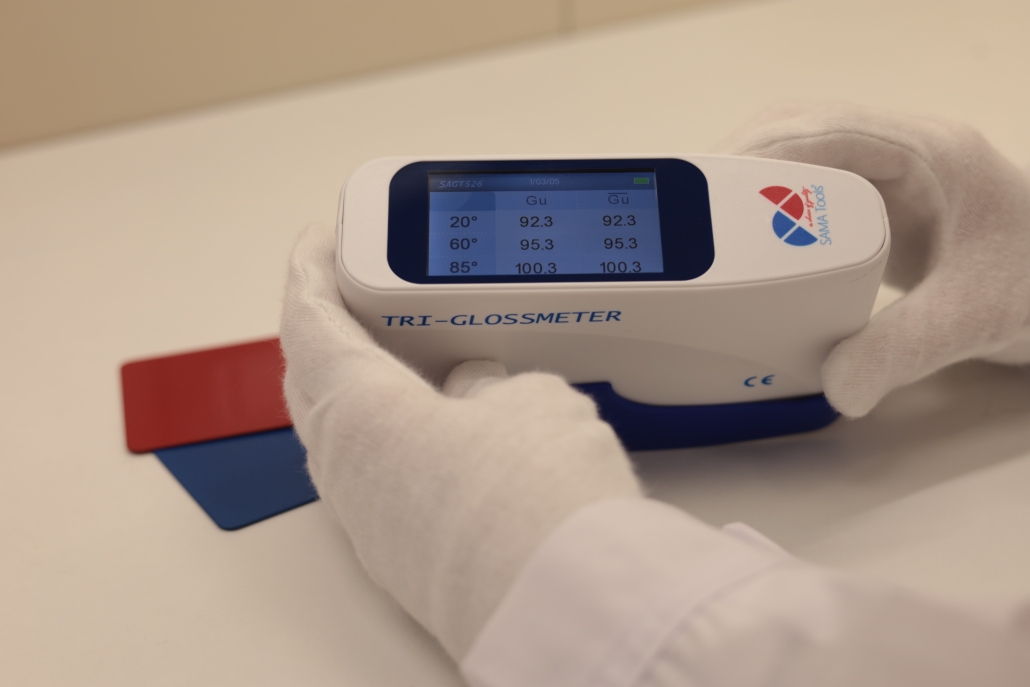

The SAGT526 high range tri-angle glossmeter by SAMA Tools is an indispensable tool for those who work in the painted and polished surfaces industries. Thanks to its three measuring angles, this glossmeter allows you to obtain precise and reliable measurements regardless of the degree of gloss of the surface.

As already mentioned, this tool is designed to measure the gloss of a surface without damaging it, which makes it ideal for use in a wide range of industries. With an extended measuring range, automatic calibration and high accuracy, this instrument is one of the most professional available on the market.

One of the main advantages is its ability to provide reliable and reproducible results. This is particularly important in fields like the automotive industry, where vehicle surfaces must be high quality and meet the high shine and gloss standards set by car manufacturers.

Why buy a SAMA Tools glossmeter?

There are several reasons why buying a SAMA Tools glossmeter is a good idea for quality control in any company. Here are a few:

- Precision: The glossmeter provides precise and reliable measurements of surface gloss.

- Repeatability: The glossmeter provides repeatable results, so consistent results can be achieved for every measurement. This is very important to ensure the quality of the products.

- Non-destructive: It’s a non-destructive instrument, so it doesn’t damage the surface during the measurement. This makes it ideal for surfaces that cannot be damaged during quality control.

- Easy to use: It’s an easy tool to use and has a digital display that makes reading the results clear and simple.

- SAMA Tools Guarantee: Thanks to the numerous positive reviews we’ve recieved, you can be sure you’re making a quality purchase.

Why should you calibrate your glossmeter?

The calibration of the glossmeter can be seen as a “snapshot” of the state in which the device is at that particular moment in time. It provides information about the accuracy and reliability of the instrument, as well as revealing any problems or defects that could affect its ability to provide accurate results. Furthermore, it can be used as a reference to evaluate the evolution of the instrument over time and verify whether it is still able to provide reliable results.

Therefore, it’s important to calibrate the glossmeter because this important process allows one to check the operating status of the instrument and ensure its accuracy and reliability.

What are the risks associated with using an uncalibrated instrument?

Not performing periodic calibrations, may result in inaccurate readings that could affect business decisions or the quality of the finished product. Furthermore, calibration is important to ensure that the instrument always delivers accurate results, regardless of whether it hasn’t been used for a long period of time or if it’s been subjected to harsh environmental conditions.

Secondly, calibrating the glossmeter can help to identify any problems or defects that the instrument may have, which, once resolved by means of fine-tuning, allow to obtain reliable results again.

In conclusion, purchasing a glossmeter for quality control can be a good idea for the many industries that work with painted and polished surfaces. The glossmeter offers accuracy, repeatability, non-destructiveness and is easy to use, making it an ideal tool for ensuring the quality of surfaces.

If you’ve enjoyed reading about the glossmeter, we think might be interested in reading about measuring color and brightness.

Don’t hesitate to contact our team of experts for more information and fill out the form. S.A.M.A. Italia can help your company ensure the high quality of your product surfaces, and the calibration of your equipment.